Home>News

How to calculate the gram weight of non-woven fabrics?

- 2025-07-04

The price differences of different types of non-woven fabrics are mainly in terms of material, process, gram weight, color, special width, etc.

Only by knowing the specific gram weight (thickness), width, color, quantity, and roll length of non-woven fabrics can the standard net weight and total price of each roll of fabric be accurately calculated.

Non-woven fabrics have different thicknesses and advantages. In order to accurately calculate the price of non-woven fabrics, it is generally necessary to accurately calculate the gram weight of non-woven fabrics.

Calculation method of gram weight of non-woven fabrics

Gram weight refers to the gram weight per square meter, that is, grams/square meter.

68gsm cloth refers to 68 grams/square meter, which means that the weight of one square meter is 68 grams, which is used to measure and distinguish the thickness of the fabric.

Gram weight is used to calculate the thickness of non-woven products. Why not use millimeters? In fact, millimeters are also used, but they are rarely used. This is an industry rule for easy calculation.

In fact, square weight is equivalent to millimeters in thickness. The regular weight of non-woven fabrics is between 10g/㎡ and 320g/㎡. Some needle-punched fabrics can achieve thicker weights.

In addition to non-woven fabrics, the calculation methods of other Oxford bags, nylon bags, cotton bags, and canvas bags are similar, but the units are different.

How to measure the weight of non-woven fabrics?

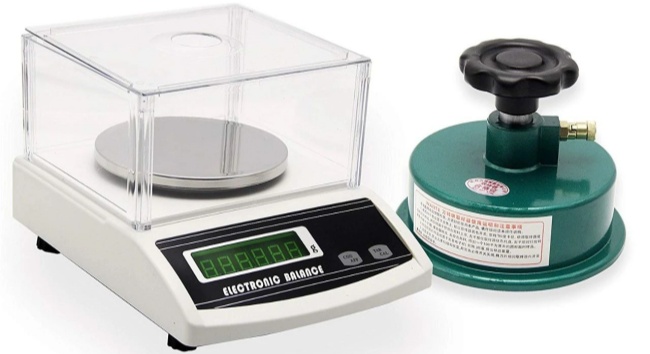

To calculate the weight of non-woven fabrics, there are special measuring tools, cutters and electronic scales in the industry.

The measurement method is as follows:

1. Cut a small piece of non-woven fabric and fold it in half several times;

2. Use a cutting tool to cut out pieces of cloth of the same size (round or square);

3. Weigh the weight of each piece, add the total weight and divide it by the quantity (this is more uniform and accurate);

Due to the non-woven fabric industry, the production process and technology of each factory are different, and the weight produced is biased.

For example, if the order specification is 70gsm, not every piece will be exactly 70gsm after weighing. Generally, we try to control it within the gram weight deviation range allowed by the industry.

Depending on the material and thickness of different types of non-woven fabrics, the gram weight of non-woven fabrics is also different. Each non-woven fabric manufacturer has similar calculation methods for the gram weight of different types of non-woven fabrics.

- Previous article:Spunlace Nonwoven Fabric Price: Key Factors That Drive Your Cost

- Next article:Processing methods of bio-based chemical fibers