Printed Spunlace Wipes are increasingly favored by global buyers and cleaning supply chains for their advantages of “easy identification, strong performance, low linting, and customizability.” In food processing, professional cleaning, hospitality services, industrial manufacturing, and other related industries, **cross contamination** remains one of the most critical hygiene management challenges.

Why does cross-contamination frequently occur in professional cleaning?

A single cloth is used across multiple zones

Workers cannot distinguish wipe purposes, leading to cross-use

Lack of clear visual separation causes tool management chaos

Inconsistent cleaning protocols across zones

Therefore, businesses must enhance cleaning system control through “visual identification + premium materials,” making printed spunlace wipes the ideal solution.

How do dyed spunlace wipes reduce cross-contamination?

1. Implement “visual zone management” through printing:

Blue - General use

Red - Bathrooms, toilets

Brown - Coffee

Yellow - Hospitals, clinics

Green - Food preparation, kitchens

Dyeing enables dual identification by “zone + function,” making it ideal for SOP (Standard Operating Procedure) systems in large factories or professional cleaning companies.

2. High-quality spunlace materials prevent cross-contamination, which often stems from material shedding.

Printed spunlace wipes utilize:

Viscose / Polyester

Wood Pulp / Polyester

These materials offer:

High strength

Superior water and oil absorption

Resistance to tearing when wet

Low lint shedding

Ensuring no secondary contamination during wiping.

Why are printing and dyeing spunlace wipes more popular?

1. Superior material performance for specialized applications

2. Stable factory production capacity ensures bulk supply

3. Comprehensive certifications meet global client audits. Depending on material composition, we provide:

FSC / PEFC (sustainable wood pulp sourcing)

RoHS / MSDS (material chemical safety)

EDANA, SGS, Intertek testing

Suitable for export cleaning supplies, industrial wipes, and wet wipe raw material audits.

4. Versatile applications for multi-product line development

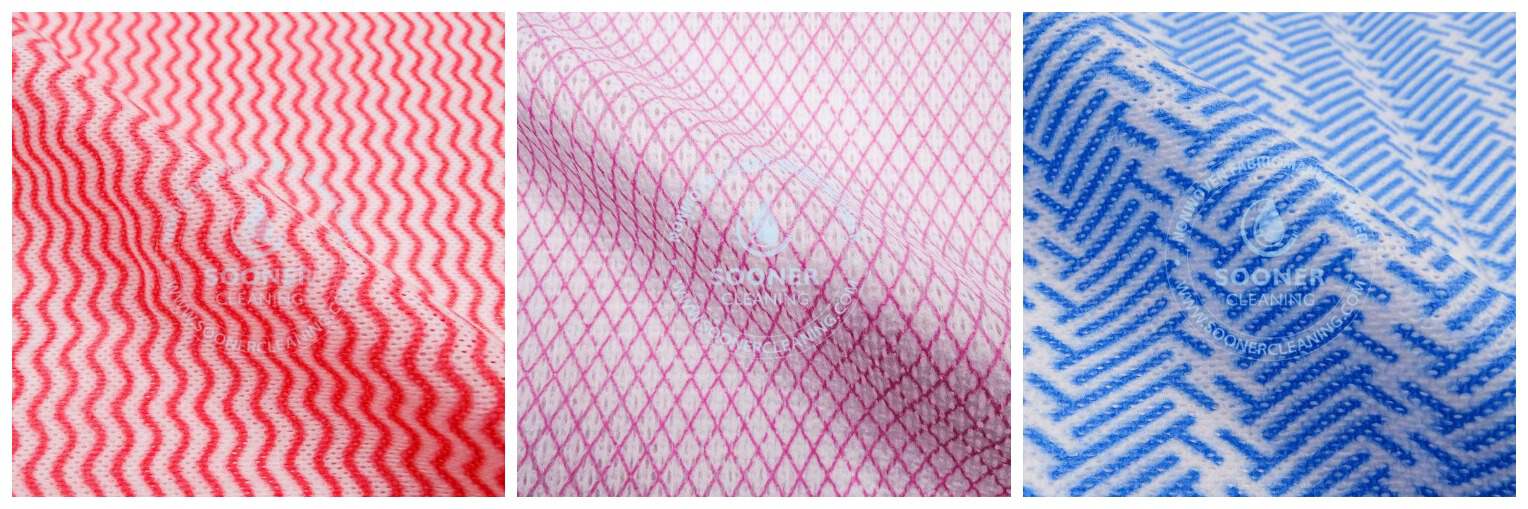

5. Diverse customization options for competitive differentiation: printable patterns, grammage, width, mesh patterns, etc.

Conclusion